Top 8 Refractory Cement Home Hardware

Finding your suitable readers for refractory cement home hardware is not easy. You may need consider between hundred or thousand products from many store. In this article, we make a short list of the best readers for refractory cement home hardware including detail information and customer reviews. Let’s find out which is your favorite one.

977 reviews analysed

MEECO’S RED DEVIL 611 Refractory Cement – Indoor Use Only

Product Description

A pre-mixed, fiber-reinforced, high temperature silicate mortar for setting, coating or repairing firebrick. Used extensively as the mortar between firebricks when building fireplace fireboxes. Will withstand temperatures up to 3000-Degree F. Requires heat to cure. Buff color.

From the Manufacturer

A pre-mixed, fiber-reinforced, high temperature silicate mortar for setting, coating or repairing firebrick. Used extensively as the mortar between firebricks when building fireplace fireboxes. Will withstand temperatures up to 3000-Degree F. Requires heat to cure. Buff color.

Rutland 12.5 lbs Tub Castable Cement – Mix With Water (Fire Clay) 2200 degree

- Easily fix large masonry holes or cracks in your indoor or outdoor fireplace, stove, or other heating appliance

- Build a solid fire pit floor or mold into custom firebrick shapes, the possibilities are endless

- No heat cure required making your project much easier

- 25 pounds will cast a 12″ x 12″ x 3″ block

- For interior or exterior use, rated to 2,200 Degrees F (1,200 Degrees C)

Rated up to 2200 DegreeF (1200 DegreeC). used to cast custom shapes, to Replace worn-out firebrick or fill large holes in the Masonry firebox.

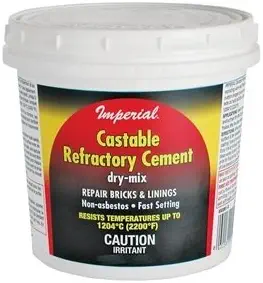

Cement Refactory 3lb Buff

Dry mix Size: 3 lbs Color: Buff Repairs bricks and linings Fast setting and non-asbestos Can be used indoors and outdoors Can be cast into custom shapes or as one solid stove bed Resists temperatures up to 1204 Deg. C (2200 Deg. F)

MEECO’S RED DEVIL 610 Refractory Cement – Indoor Use Only

Product Description

A pre-mixed, fiber-reinforced, high temperature silicate mortar for setting, coating or repairing firebrick. Used extensively as the mortar between firebricks when building fireplace fireboxes. Will withstand temperatures up to 3000-Degree F. Requires heat to cure. Buff color.

From the Manufacturer

A pre-mixed, fiber-reinforced, high temperature silicate mortar for setting, coating or repairing firebrick. Used extensively as the mortar between firebricks when building fireplace fireboxes. Will withstand temperatures up to 3000-Degree F. Requires heat to cure. Buff color.

Rutland Products Black, 32 fl oz Furnace Cement

- Great cement for small repairs or big rebuilds, easy to use and clean up

- Smooth consistency cement bonds and seals metal to metal or metal to masonry joints

- Repair stove cracks and seals, reset firebrick, attach your stove collar, glue ceramic logs

- Rated to withstand up to 2000° F (1090° C)

This has been the benchmark Furnace Cement for over 90 years. Rutland Furnace Cement is a pre-mixed silicate cement that withstands temperatures over 2000° Fahrenheit without failure. The smooth consistency feathers very thin to make metal-to-metal joints smoke and gas tight. For installation and service of furnaces and oil burners. Seals flues and coal or ash pit doors. Also for small woodstove repairs.

Rutland 211 Fireplace Dry Mix Patch

- Refractory mortar that is ideal for joining or repairing masonry flue tile in any gas or wood fireplace and wood, coal, or pellet stove chimney

- Can be used as a parge coating (thin over-coat) when building or repairing fireboxes

- Dry mix cement, just add water and trowel into place

- Dark grey finish

- For interior use, rated up to 2550°F (1400°C)

WoodEze specializes in the manufacturing and distributing of top quality products so that you can enjoy using them. They utilize their power to pass on great products and extreme savings to you. With more than 32 years experience in the fireplace and hearth industry Woodeze understands your needs better than anyone. They have everything you need to get your fireplace up and running fast including all the little aspects and all in high quality. Dry Mix 211 is a refractory mortar used for joining or repairing masonry flue tile or as a parge coating for building fireboxes. Non water soluble amp;#44; this product is a hydraulic set mortar that does not require heat to cure amp;#44; and it resists washing out when exposed to rain or water. Dry Mix 211 Develops a compressive strength above 2500 psi and withstands 2550 Fahrenheit without softening. Acid resistance meets or exceeds all the requirements of the National Fire Protection Association standard NFPA 211 and NYSCMA Tek Spec. Dark Gray color. Acid resistant Non-water soluble refractory mortar For use in building masonry flue liners Use as a parge coating in fireboxes Withstands 2550F Hydraulic set does not require heat to cure Meets or exceeds NFPA 211, 1988 edition Meets or exceeds NYSCMA Tek Spec No. 3 <li>covers 1268 square inches at 1/8th of an inch thick approximate 50 clay flue tiles 8 Inch x 8 Inch or 30 at 4.5 Inch x 9 Inch fire bricks

Rutland 611 Refractory Cement, 1 Gallon Capacity

A pre-mixed cement for masonry to masonry repairs 1/8” – 1/4” thick. Meets ASTM E136 and E72. Use to set, coat, or repair fire brick in fireboxes. Rated to withstand up to 2000 degreeF. Requires heat to cure. May be painted once heat cured. Buff.

94% Alumina Dense Castable Refractory Cement 55 Lbs.

94% Alumina Dense Castable Refractory Cement 55 lbs.

Manufactured By: Caldreys India refractories limited

- Specification

- Material : Refractory Castable

- Type : 94% High Alumina Dense castable

- Nature of Bond : Hydraulic

- Installation : Vibration casting

- Max. Service Temperature : 3270 °F/1800°C

- Maximum Grain Size : 5 mm

- Water Required For Casting : 8.0 to 9.5%

Tabcast-94 is 94% alumina, hydraulic setting dense Castable, which is suitable for service temperature up to 3270°F (1800°C). It is premixed refractory compositions which can cast into any require shape and size. It has good mechanical strength with excellent resistance to chemical attack for having purity chemical content. 22 pounds will cast a 12’’ x 12’’ x 1½’’ block. it also use for reformer lining, transfer and riser lining, hydro cracking unit line, in petrochemical industry, coal gasification ducting, Cyclones, Burner pipe lining, iron ladles, in metal processing industry.

- Application

- High Velocity area

- High dust erosion area

- Iron Ladles

- High temperature boiler inlet

- Thermal combustors

- Hydrogen transfer line

- Ammonia reformer line

- High temperature burner blocks

- Coal gasification ducting

- Characteristics

- High Purity chemical content present

- Good Mechanical strength

- Excellent resistance for chemical attack

- It can resist temperature up to 3270°F (1800°C)

- Able to resist corrosion erosion

- Can resist high temperature for hydrogen service

Conclusion

By our suggestions above, we hope that you can found Refractory Cement Home Hardware for you.Please don’t forget to share your experience by comment in this post. Thank you!

Our Promise to Readers

We keep receiving tons of questions of readers who are going to buy Refractory Cement Home Hardware, eg:

- What are Top 10 Refractory Cement Home Hardware for 2020, for 2019, for 2018 or even 2017 (old models)?

- What is Top 10 Refractory Cement Home Hardware to buy?

- What are Top Rated Refractory Cement Home Hardware to buy on the market?

- or even What is Top 10 affordable (best budget, best cheap or even best expensive!!!) Refractory Cement Home Hardware?…

- All of these above questions make you crazy whenever coming up with them. We know your feelings because we used to be in this weird situation when searching for Refractory Cement Home Hardware.

- Before deciding to buy any Refractory Cement Home Hardware, make sure you research and read carefully the buying guide somewhere else from trusted sources. We will not repeat it here to save your time.

- You will know how you should choose Refractory Cement Home Hardware and What you should consider when buying the Refractory Cement Home Hardware and Where to Buy or Purchase the Refractory Cement Home Hardware. Just consider our rankings above as a suggestion. The final choice is yours.

- That’s why we use Big Data and AI to solve the issue. We use our own invented, special algorithms to generate lists of Top 10 brands and give them our own Scores to rank them from 1st to 10th.

- You could see the top 10 Refractory Cement Home Hardware of 2020 above. The lists of best products are updated regularly, so you can be sure that the information provided is up-to-date.

- You may read more about us to know what we have achieved so far. Don’t hesitate to contact us if something’s wrong or mislead information about Refractory Cement Home Hardware.